T. S. Eliot said that “immature poets imitate; mature poets steal.” In other words, transforming known material is more sophisticated than attempting an inferior likeness.

Something similar is true regarding the stuff that poets write on, according to John Dancy-Jones. The Asheville papermaker finds that his best writing stock takes its life from the repurposing of other material.

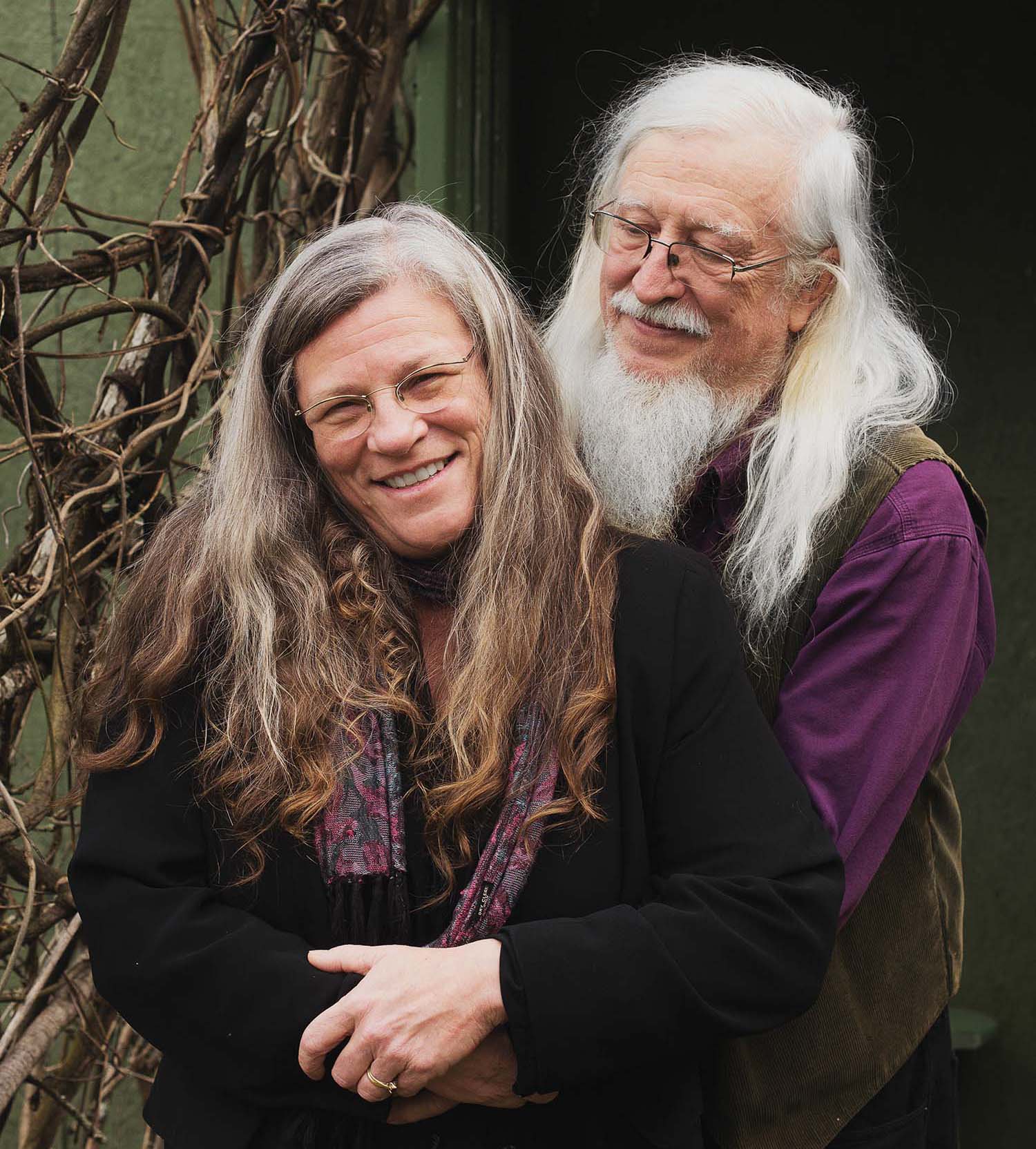

“From Gutenberg on, European papermakers were recyclers, just like me,” Dancy-Jones says. At The Paper Plant, the home studio he shares with his wife Cara, the couple transforms leftover textile trimmings and scraps from art studios into handmade paper sheets, notecards, and books.

John was the first of the two to learn the craft, developing his process in the basement of the University of North Carolina at Greensboro’s Jackson Library. In 1985, he taught papermaking to Cara so the couple could make their own wedding invitations. “We tore up pieces of old romances we’d given each other and put them in the pulp,” John recalls. “We literally had something old and new, borrowed and blue in there.”

Those old books are long gone, but the papermakers have no worries about running out of raw materials. Before moving to Asheville, John ran The Paper Plant as a bookstore in downtown Raleigh, where he developed a symbiotic relationship with many of the city’s printers and artists.

“Once or twice a year, I’d take a tub of scrap and leave them a stack of handmade paper in return,” he says. “I’m still trying to use the hundreds of pounds of the stuff that I dragged up here.”

The process of breaking down and reconstituting these ingredients draws attention to paper’s essential nature as a fiber product. “If you felt wool fibers, you get felt. If you felt cellulose fibers, you get paper,” John explains. By selecting raw materials with high levels of cellulose, such as cotton or flax, he and Cara can ensure high quality in the new paper that results.

Not all of the couple’s feedstock is recycled — some of it is picked fresh from the urban-homestead garden that surrounds the studio. On plots throughout the three-acre property, John and Cara have grown their own heirloom Greek cotton and flax as papermaking materials. The couple even plans to throw okra into the mix; the slimy Southern vegetable is in the same botanical family as cotton and produces similar fibers.

This hyper-local sourcing is most evident in John and Cara’s series of floral postcards. The gently ragged edge of each card, created by a wooden tool called a deckle, provides an organic frame for inclusions of dried petals from their garden. One piece features bright-orange sunflowers, yellow Black-Eyed Susans, and dark-green artemisia leaves carefully arranged in colorful contrast.

The cards neatly sum up John’s philosophy on papermaking, which he shares through classes and work sessions offered at The Paper Plant. “When you make paper, you’re creating a visual collage,” he says. “I teach people how to paint with pulp.”

The Paper Plant, 257 Baird Cove Road, Asheville. For more information, call 919-618-6883 or visit netweed.com/paperplant.

I have had the opportunity to learn how to make my own paper with John and it was such a fun experience. He is so patient and provides so much history of the craft. I was then able to take my paper home and make my own cards for family. Every card included so much love. I am glad John and Cara are keeping the craft alive!

very interesting article — so happy to have been able to read it ..Thanks for posting it.

Sarah M

— freshman roommate to Cara Mia , Columbus Ohio