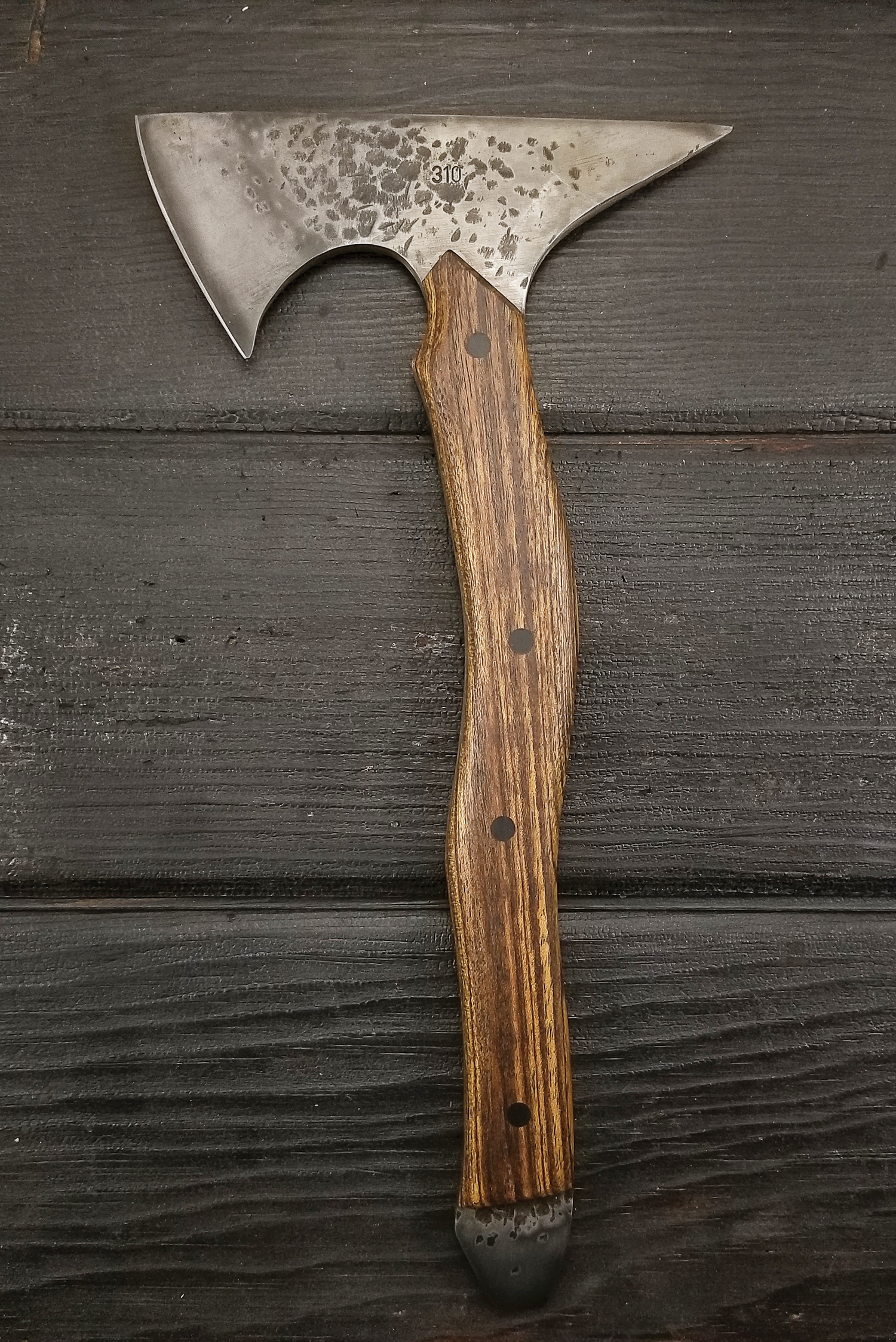

Photo by Morgan Ford

An early attempt at making a knife ended in a painful lesson for Ryan Pepper. Sharpening the blade too early in the process, “I foolishly took it to the buffing wheel,” recalls Pepper, “thinking [my] leather gloves would keep me safe.”

Instead, the buffer grabbed the knife, causing it to slice through his glove and down to the bone of his index finger. “I now have a numb finger and I’m out $3,000 in medical bills. That will probably be the most expensive knife I ever make,” he jokes. Despite almost losing a digit, “I was still hooked [on knife making], and once I recovered, I jumped back in” — this time much more carefully.

Crafting knives began as a fun hobby for the former welder, but his art has continued to evolve. More and more people began ordering Pepper’s pieces, and last year, he got to quit his day job and focus on knives. “Fortunately,” he adds, “I have a very supportive wife.”

Pepper first sketches his ideas, and when he’s happy with the design, he cuts it out of plywood. Using that wood template, he transfers the design onto the steel. After cutting the design from the metal, he begins refining the blade’s shape with an angle grinder and other tools.

Photos by Morgan Ford

“I leave the edge pretty thick to start with, and do my heat-treating process to make the steel hard and usable,” he says. This stage involves heating the steel to around 1450 degrees Fahrenheit, followed by rapidly cooling it in oil or water. The process locks the metal alloys in place. The knife is now hard as glass — but, like glass, it will break if dropped. So the steel is tempered back down in the oven, but at a much lower temperature. Then it’s time to sharpen the blade, using power tools followed by hand sanding to remove all the grinder marks.

Pepper’s knives are distinguished by the “hamon line” created during the hardening process. “It’s the wavy line found on most of my knives. I apply high-temp clay along the spine of the blade in my desired pattern,” he explains. Sometimes, he says, the pattern has a mind of its own and barely resembles what he’d intended. It’s only somewhat controllable: “The result [is] 70% science, 20% luck, and 10% magic.”

Unlike most commercial knives made of stainless steel, Pepper’s blades are fashioned from carbon steel. “It holds an edge very well,” he says, “and has a unique finish. It will patina, which is beautiful in its own right, but will rust if not kept clean and oiled.”

The artisan handles are the true mark of distinction. “Colored resin and burl wood are by far my most popular. They’re never the same,” he says. He’s also made handles form exotic woods, antlers, buffalo and ram horns, and reconstituted gemstones.

Through his enterprise, 310 Knife Co (named for the Bible verse found in Joel 3:10: “Beat your plowshares into swords …), Pepper makes chef cutlery and hunting and tactical knives, almost all of them through custom orders.

“It’s not anything I really expected when I first started, but it’s pretty amazing to be doing it. I literally just make cool stuff in my garage, on my own terms, blasting music — and somehow it’s paying my bills.”

Ryan Pepper, Asheville, 310 Knife Co. For more information, see 310knifeco.com.

Still trying to reach Ryan

Dr. Silverman. 7128993620

Really enjoyed this! Ryan’s journey shows how passion, grit, and a bit of trial and error can turn a hobby into something amazing. The fact that he kept going even after nearly losing a finger makes the craftsmanship behind those knives even more impressive. Love how his blades balance art, grit, and real-world use. Keep forging ahead!